2024-01-08

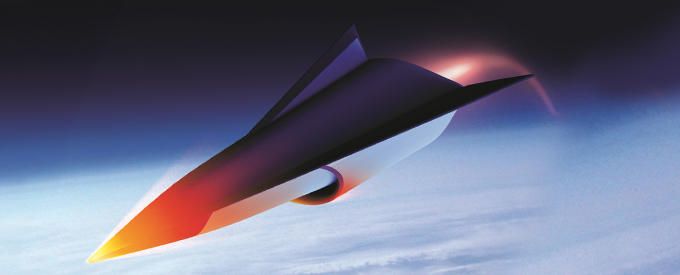

GE Displays World’s First Hypersonic Dual-Mode Ramjet

GE Aerospace lifted the curtain on its comprehensive Hypersonic Programme at its Research Centre in Niskayuna, demonstrating what is believed to be a world’s-first Hypersonic Dual-Mode Ramjet (DMRJ) rig test with Rotating Detonation Combustion (RDC) in a supersonic flow stream.

The Programme could help enable high-speed, long-range flight with increased efficiency. The latest milestone and overall portfolio of programmes position GE Aerospace to pursue multiple opportunities in the sector as it prepares to launch as a standalone company in Q2 of 2024.

The new architecture with RDC could power super-efficient hypersonic vehicles with extended ranges exceeding MACH-5 or >4,000 MPH. The high-speed propulsion programme is part of a broad portfolio of capabilities and scale that GE Aerospace brings in high-temperature materials and electronics, thermal management, and high-speed aerodynamics to propel hypersonic vehicles.

The DMRJ demonstration is part of a comprehensive portfolio GE Aerospace is developing to advance hypersonic capabilities, including high-temperature materials and electronics. These technologies are the products of over a decade of direct hypersonic-related efforts run by GE Aerospace Research and several decades of developments for its engine business in critical areas like high-temperature Ceramic Matrix Composites (CMCs), Silicon Carbide Power Electronics, Additive Technologies, and Advanced Thermal Management.

“GE Aerospace is well positioned with the right capabilities, experience, and scale to be a leader in driving new developments for our customers,” said Amy Gowder, President and CEO of GE Aerospace, Defence & Systems. “The highly successful demonstration of a DMRJ with RDC is an outgrowth of our 10+ years of RDC work, including the strategic acquisition of Innoveering that has brought leading technologies and experience in hypersonic propulsion and Ramjets.”

Extended Range

GE Aerospace engineers are working on a rotating detonation-enabled dual-mode Ramjet capable of handling at lower MACH numbers, enabling the flight vehicle to operate more efficiently and achieve more extended range.

The acquisition of Innoveering last year gave its dual-mode Ramjet engine capabilities rapidly augmented with GE Aerospace Research’s decades of work in RDC and several decades of experience in high MACH research and engine development programmes. RDC enables higher thrust generation more efficiently, at an overall smaller engine size and weight, by combusting the fuel through detonation waves instead of a standard combustion system that powers traditional jet engines today.

“The successful development, integration, and demonstration of GE’s unique technologies and capabilities will position us to provide differentiating hypersonic propulsion systems for our customers now and well into the future,” said Mark Rettig, Vice President and General Manager of Edison Works Business & Technology Development, GE Aerospace. “We have assembled the right expertise, with the right capabilities, and invested strategically to ensure we are aligned very closely with the needs of our customers. The significant results we have had to date give us confidence that we are moving in the right direction,” he said.

Rettig added that it took the team just 12 months from start to finish for the DMRJ with RDC demonstration and it is on track with its goal to demonstrate a full DMRJ with RDC at scale next year. The development of high-speed Ramjet propulsion capabilities is a critical anchor point of other key advancements in hypersonic technologies, including:

High-Temperature Materials: GE Aerospace is an Original Equipment Manufacturer (OEM) using ceramic matrix composites in the high-pressure turbines on commercial aircraft. These decades of material innovation in superalloys have delivered higher temperature capabilities and durability, enabling commercial engines to operate more efficiently over time.

High-Temperature Electronics: GE Aerospace researchers recently demonstrated the first Silicon Carbide (SiC) MOSFETs (Metal–Oxide–Semiconductor Field-Effect Transistors) that is believed to operate at temperatures exceeding 800 degrees C. Other recent advancements in SiC technology have created scalable 600C-capable electronics to control and monitor hypersonic vehicles in extremely high-temperature operating environments.

GE Aerospace has amassed a leading IP portfolio in SiC over two decades. It offers SiC-based electrical power products with power levels for harsh environments in aerospace, industrial, and military applications.

GE’s SiC MOSFETs could support the development of more robust sensing, actuation, and controls that open new possibilities in space exploration and enable the control and monitoring of hypersonic vehicles traveling at MACH-5 speeds. That is more than six times the speed of a typical commercial passenger flight today.

No Comments