2014-08-01

Raytheon EKV ballistic missile destroys target in space

First successful intercept for latest variant

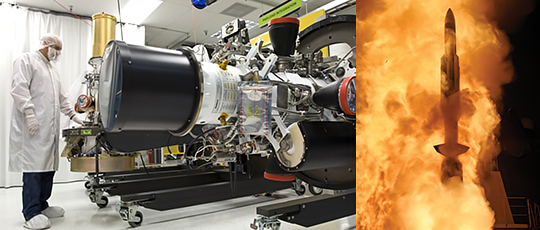

A ground-based interceptor roars into the sky carrying a Raytheon-built Exoatmospheric Kill Vehicle on June 22, 2014 ... the kill vehicle destroyed a simulated ballistic missile high over the Pacific Ocean.

Raytheon’s EKV destroyed an intercontinental ballistic missile target in space, marking the first successful intercept for the latest variant of the EKV and the ninth for the overall program.

The intercontinental ballistic missile target used in the test was launched from the Ronald Reagan Ballistic Missile Defense Test Site on Kwajalein Atoll in the Pacific Ocean, while the Ground-based Interceptor was fired from Vandenburg Air Force Base in California.

Once in space, the interceptor released the EKV, which identified the target, tracked it and destroyed it. EKVs carry no warheads and eliminate targets by force of impact alone.

“This is an important moment for our nation (US),” said Dr. Taylor W. Lawrence, president of Raytheon Missile Systems. “The successful test reflects the tireless systems-engineering work by a joint government-industry team to ensure the US is protected from long-range ballistic missiles.”

The intercept took place during a Missile Defense Agency test of Boeing’s Ground-based Midcourse Defence System, which is designed to protect the US against long-range ballistic missile attack by destroying incoming threats in space.

Partner

As prime contractor since 1998, Boeing has partnered with the US Missile Defense Agency in the design, development, integration, test and sustainment of all GMD components.

Key subcontractors include:

• Northrop Grumman (strategic partner) - fire control and communications products as well as support to systems engineering, systems testing and operations and sustainment

• Raytheon - GBI Exoatmospheric Kill vehicles (EKVs)

• Orbital ATK - GBI booster vehicles

Boeing continues to lead the industry team for GMD development, integration, testing, operations and sustainment activities under the Development and Sustainment Contract, which was awarded in December 2011. The company will continue to build on its experience of supporting the Missile Defense Agency as prime contractor for the program.

Under rigorous testing, the GMD system has demonstrated impressive capabilities, including the ability to shoot down an incoming ballistic missile. The system has achieved a total of eight successful intercept tests, including three successful intercept tests with operationally-configured interceptors. Flight testing is scheduled to continue.

In addition, Boeing continues development of the two-stage interceptor in order to provide a hedge against the long range ballistic missile threat. Boeing and MDA have executed a successful two-stage launch, fly-out and data collection mission.

Latest design

The performance of the EKV in this test builds on last year’s successful non-intercept flight test and validates the latest design, known as the “CE II” variant.

The EKV locks on and eliminates high-speed ballistic missile warheads in space using nothing more than the sheer force of impact, known as a “hit-to-kill” defense.

“Raytheon is 100 per cent committed and invested in providing innovative, reliable kill vehicles for the protection of the US,” said Wes Kremer, vice president of Air and Missile Defense Systems.

“Today is proof that we have fully resolved the issues discovered in previous tests, and I am confident in the system deployed today.” Kremer said Raytheon supports the need for a redesign to the current EKV, which was originally deployed by presidential decree in prototype status in 2004.

“Today’s test allowed us to challenge the EKV in a series of realistic outer-space environments, which gives us a broad range of data prior to moving toward an intercept scenario,” said Wes Kremer, Raytheon’s vice president of Air and Missile Defense Systems.

Confidence

A target missile launch was not planned for this flight test. After performing fly out maneuvers, the three-stage booster deployed the Exoatmospheric Kill Vehicle to a designated point in space. After separating from the booster, the Exoatmospheric Kill Vehicle executed a variety of pre-planned maneuvers to collect performance data in space.

“This is the most complex missile defense mission in the world, and it requires the most advanced kill vehicle in the world,” said Steve Nicholls, Raytheon’s EKV program director. “The EKV performed extremely well today, and I have great confidence that we’ll be able to move toward an intercept flight test this year.”

The EKV leverages more than two decades of expertise in kill vehicle technology. It has an advanced, multi-color sensor that detects and discriminates incoming warheads from other objects. The vehicle also carries its own propulsion, communications link, guidance and control system, as well as computers to support target selection and intercept.

“Raytheon supports a robust EKV redesign that further increases reliability, testability and maintainability of the fleet,” Kremer said. “We know exactly what it will take to mature the EKV from its prototype status into a mature, consistently performing program, and we can do it while significantly reducing costs.”

Space factory

That sentiment was echoed by Sharon Walk, director of Raytheon’s Space Systems Operations, who oversees the Space Factory where the EKV and Standard Missile-3 kill vehicles are made.

On the outskirts of Tucson, Arizona, one of the cleanest factories in the world runs a one-of-a-kind operation: creating rocket-propelled “kill vehicles” that hunt down and destroy ballistic missiles in space.

Here, workers in clean-room suits assemble optics and sensors so sensitive that they can pick out warheads against the blackness of space from hundreds of miles away. Others install tiny thrusters so accurate they can steer into the path of a missile moving at 17,000 mph.

This is Raytheon’s Space Factory, a workshop that is like no other in the world. Cleaning crews constantly clean the floors and scrub surfaces with alcohol wipes. Pumps replace the air in some labs every 27 seconds.

“We have some very key people here and key infrastructure that doesn’t exist anywhere else,” said Walk.

The Space Factory and its clean room technologies have helped make Raytheon the world leader in space-based kill vehicles. The company has decades of experience building interceptors for the Ground-Based Midcourse Defense system and the Standard Missile-3, and it is now expanding the Space Factory to develop the next generation of kill vehicles.

In the factory, stainless steel is the metal of choice for the myriad of test chambers used to simulate the chill of space. Sensors throughout the building constantly measure air pressure, humidity and microscopic particles of dirt.

Even the dirtiest areas are cleaner than an operating room, and technicians use tools that go through a special rinsing process. Workers with colds aren’t even allowed in the clean rooms for fear they might sneeze and cause contamination.

Raytheon opened the factory in 2002 after the US government tasked the company with building a system to counter the rising threat of long-range ballistic missiles. It designed and rapidly deployed an exoatmospheric kill vehicle prototype two years later.

The prototype model is now flying on the ground-based interceptor missiles used by the Ground-Based Midcourse Defense system. The company has continued to refine its designs, and the kill vehicle now used on the Standard Missile-3 incorporates these advances.

Expertise

“Over time, we were able to leverage knowledge from the prototype and expand that into the SM-3 product line, producing three variants,” Walk said. The latest SM-3 variant achieved five-for-five intercepts last year.

Cleanliness is key to Raytheon’s success because a kill vehicle’s optics and sensors have to be absolutely clear to pick out fast-moving targets against a field of stars, said Vic Wagner, director of advanced kill vehicles for Raytheon Air and Missile Defense Systems.

“We’re measuring photons. That’s how tight we are,” he said.

Makers of computer chips only have to protect flat wafers, but the Space Factory has to keep three-dimensional objects clean – a far more difficult task, Wagner said.

“A clean room in the semiconductor industry is not designed to build kill vehicles,” Wagner said. “We’ve built the infrastructure of air handling and test equipment that’s second to none.”

The factory is divided into three cleanliness classes. Only four to five people are allowed in the most restrictive zone.

But machinery and cleanliness aren’t the only unique things about the Space Factory. The people who work in the labs have spent decades perfecting interceptor technology, a specialty shared by no other company in the world. In Tucson they rub elbows with the world’s foremost missile designers as well.

“It truly is a fertile ground and springboard for sharing knowledge,” Walk said.

To prepare for the next-generation kill vehicle, the company is expanding the factory by almost 6,500 square feet and adding an even cleaner “microenvironments” area. The new addition will include more automation and is expected to be finished by year-end.

“We invented the business of building kill vehicles to defend the free world, and we’re now ready to employ our collective knowledge, expertise and infrastructure to take it to the next level,” Walk said.

Raytheon kill vehicles are built by the same engineers using the same equipment, and the lessons learned on the highly successful SM-3 program will be applied to future generations of EKV, according to Walk.

“We have the talent, technology and manufacturing equipment to not only support current designs, but also to stay ahead of future ones,” Walk said.

Credit: www.raytheon.com

No Comments